A prosthetic device served as a substitute of a specific limb like hands or legs to be functional the way they are intended to. Interested in this prosthetic limbs, two Biomedical Engineering student at Universitas Dian Nuswantoro (Udinus) invented an economical and humane prosthetic leg known as the Silicone Partial Foot Prosthetic (SPFP).

SPFP itself is an innovation produced by these two students for people with disabilities, particularly those with damaged feet. This specific condition might be caused by congenital diseases or amputation.

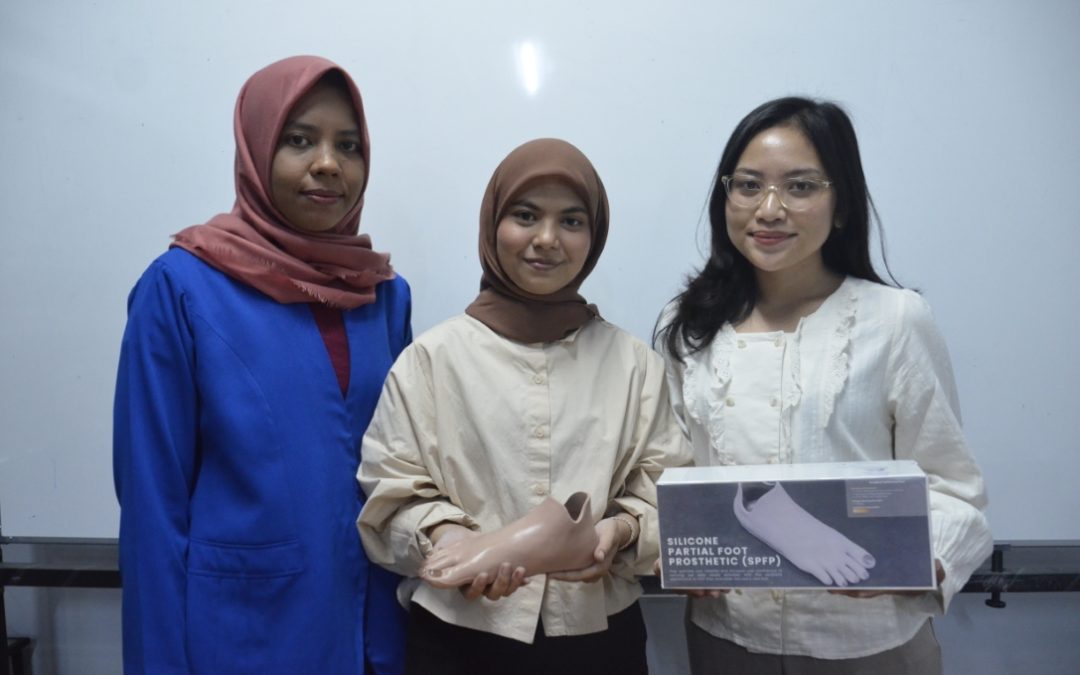

Those two students are currently undergoing their studies in the Department of Biomedical Engineering at the Engineering Faculty at Udinus. One of the designers of the Silicone Partial Foot Prosthetic, Anissa Lutfiyah Handayani, explained that her team focused on creating a prosthetic leg by utilizing 3D technology. The entire making process started with data sampling using a 3D scanner , and the data would later be printed using a 3D printer.

“We primarily used filament 3D printing the PLA to create the printing tool. As for the prosthetic leg, we used silicon as the main material. This entire making process spanned two weeks,” she explained.

“Unlike other prosthetic devices, we do not only aim for this device to meet its functional purposes, but also we would like for this prosthetic leg to match the users’ body shape, allowing them to be more confident in using this device,” Annisa added.

Furthermore, Merry Sonia Subiantoro added that research still indicated that prosthetic devices were inherently costly. For that reason, she and her team used silicon, which is generally cheaper and more common.

“It costs over ten million rupiah to produce only a prosthetic leg. Fortunately, we could push our production cost, and our newly invented device will only cost four mullion rupiah on the market,” Merry uttered.

SPFP itself is an innovation produced by these two students for people with disabilities, particularly those with damaged feet. This specific condition might be caused by congenital diseases or amputation.

It has been tested

The innovative device created by two students of the 2020 cohort has finally reached the testing stage. This device was funded through the Kedaireka Funding program proposed in 2023 by one of the partners of the Engineering Faculty at Udinus.

One of the faculty members, Dita Ayu Mayasari, ST., MBiotech, mentioned that the innovation was a part of the 2023 Kedaireka concerning prosthetic legs. Moreover, the Biomedical Engineering Department also has a medical rehabilitation learning program. In this program, students will be taught how to create prosthetic devices.

“With this innovation, we hope for this product to gain popularity among the general public, as well as benefit people with disabilities. To do this, we would like to tie collaborations with various prosthetic clinics,” she hoped.

Thus far, they have patented the manufacturing procedure, namely, the manufacturing module of prosthetic legs based on 3D technology. (Humas Udinus/Haris. Foto: Humas Udinus)