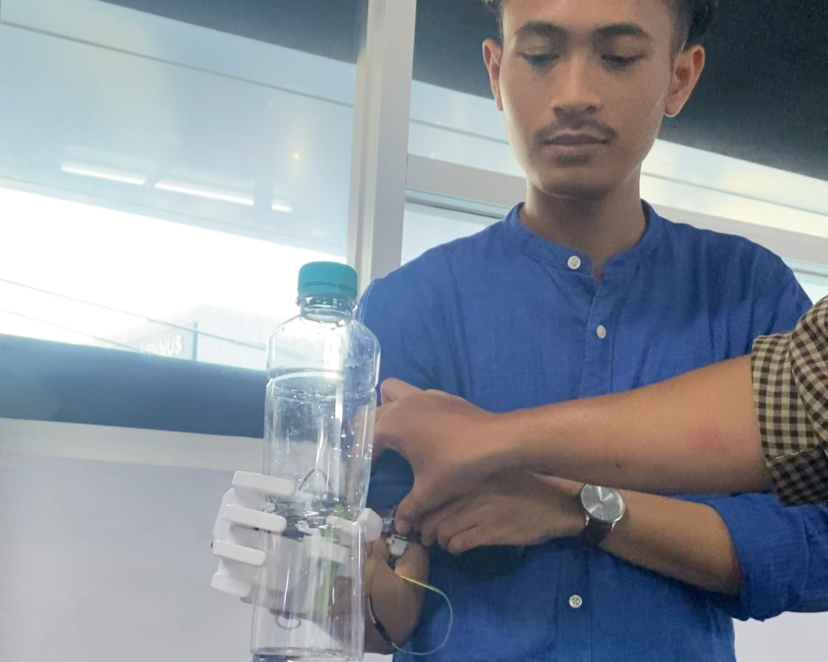

Various innovations continue to be brought up by Universitas Dian Nuswantoro, (Udinus). Presently, students of the Bachelor of Biomedical Engineering Program once again created a robotic arm. The robotic hand is called the Force Sensing Resistor (FSR) the Hand Prosthetic.

Dinara Diaz Pramono and M. Rifqi Hanif Amrullah are the proposers of making this prosthetic hand. This can help people with disabilities to do their daily activities. They are encouraged to make FSR due to many disabilities people need prosthetic hands. Both of them took approximately six months to build the prosthetic starting from the designing step to the validation step by an orthopedic doctor.

During the manufacturing process, they encountered problems with the motor and battery parts that had errors. However, according to Dinara, raw materials for manufacturing are easy to obtain. Poly Lactic Acid (PLA) plastic was chosen because it is resistant to heat and water and is not easily damaged. Meanwhile, the way this robotic hand works is if it gives biceps muscle contraction, then this robotic hand can hold it.

Both of them hoped that their work could be truly used by the community and mass-produced. If this invention is produced massively it will not only help people with disabilities but also reveal as a product.

"At the beginning of its creation, we saw the shortcomings of people with disabilities, so most of them needed help to carry out their daily activities. Hence, we made prosthetic hands to facilitate their activities," said Dinara Diaz Pramono.

The Head of the Udinus Biomedical Engineering Bachelor Program, Dr. Ir. Aripin, M.Kom, said capstone design is one of the international accreditation requirements that is included as students' final project. This capstone design is a collaboration with industry, hospitals, and various other institutions.

"The results of this capstone design are a prototype that answers the industrial demand and are expected to be used for industry and benefit the community," Aripin explained.

Capstone Design Works

According to Dr. Ir. Aripin, M.Kom, This year there are at least 18 capstone design titles submitted by students, all of which are requests from the medical device manufacturing industry. In the future, the campus will strive to improve the quality of capstone design work of students. It can be done by involving various related stakeholders, from the beginning to the validation of the capstone design project itself.

"The design carried out by students is a collaborative project with the hospital industry, medical device companies, and so on, as a preliminary idea, which is then implemented on campus by students in the form of capstone design. Later on, it is carried out by a group of students consisting of two to three students from the seventh and eighth semesters," concluded Aripin.

In addition to the Hand Prosthetic FSR, various other innovations that can help the community have been produced by the Faculty of Engineering (FT) Udinus. For instance, the Udinus Campus Electric Tricycle (Becikku) and Silicone Partial Foot Prosthetic (SPFP). (Udinus Public Relation/Alex. Photo: PR Udinus)